PCBA

(Redirected from PCBA manufacturing)

prerequisite

- PCB must be bigger than 20 x 20 mm

Quotation Part

- BOM Materials

- PCB

- PCBA

Optional

- Other fixed cost (stencil)

File Need

BOM List: fomat XLS, XLSX, CSV

PCB Gerber

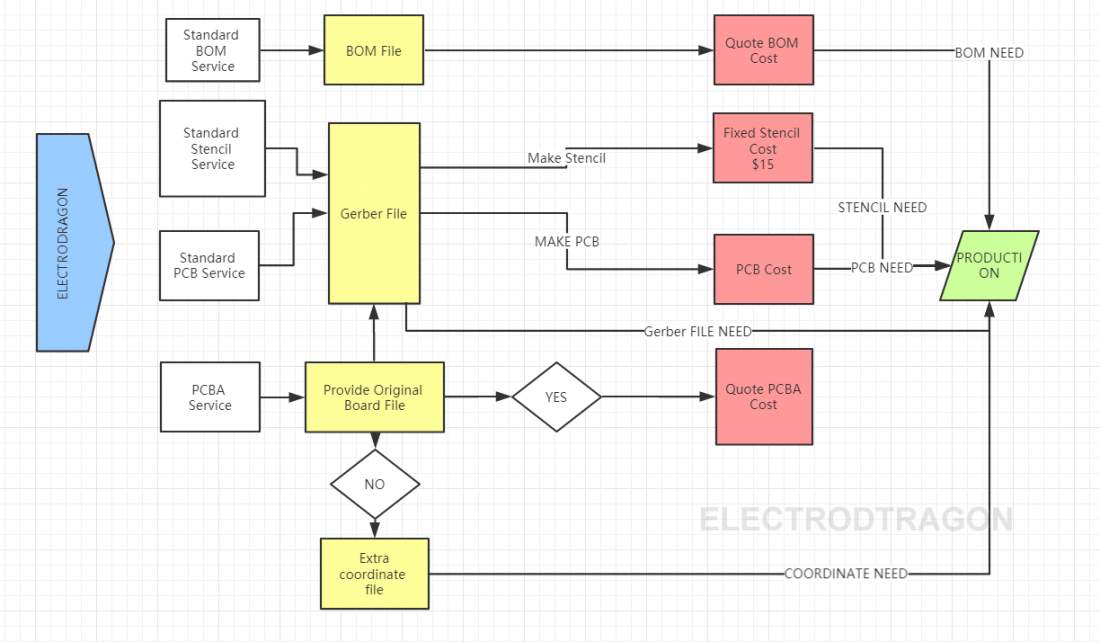

WorkFlow PCBA V1

Paypal Payment Invoice Template

Note to customer

Payment and Confirmation(if need can email images): - 1st stage. 30% for PCB - 2nd stage. 50% for PCBA - 3rd stage. 20% for shipment. * Production Lead time 10 days. * Shipment Options - Uruguay - Weight 0.45KG # DHL - $103 - 3-8 days (Use this option) # HK post - - 15-40 days. # Express PCB need to add $15, lead time -3 days.

Common Used Part

| Type | Using | Stock |

|---|---|---|

| Diode | 1N4148 1206/SOD-123 | |

| Transistor | 1N7002 | S8050, S8550 |

| Resistor | 1K, 10K, 100K | 4.7K, 0R |

| Capacitor | 0.1UF, 1UF, 10UF | - |

| ICs | AMS1117 | - |

| Button | Turtle button | - |

Note

- Only support 0805 SMD parts mininium.

- we have limited space for materials on machine, it is a small machine. So for example if you have 3 kinds of color LED, and 10pcs per board, better use only one color, can not have too much space for this.

- Because now we don't do any PCBA work for customers. So do you provide quality test method? If not we will only do visual check, this is normally fix 90% errors, quality can up to 90%. Then you can still fix the rest.

Position File

- Panelized board shoul be place on X+ and Y+ quadrant, so all parts positions should be X+, Y+

Check list

- Pick and place position file

- Part list file

- Testing method

- Slink print file

Cost Caculation

- PCB Cost

- use the following file to get your price: File:PCBA caculator.xlsx (not used) , new file here.

Panelize

- tnames/bnames will increase number when panelize.

- We normally only put tplace/bplace layers for silk print, if you need add more layers please let us know.